- A5

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

This crane is ideal for shipyards, dry docks, and loading docks where large, high-lift operations like hull repairs and segment lifting are common. It meets the needs of dockyards and shipbuilding with its heavy load capacity, wide span, high lift, and stable structure.

Six Key Advantages for Shipbuilding:

Multiple Functions – Single/double lifts, mid-air flipping, and micro-rotation for flexible operations.

Gantry Design – Single or double girder options with optimized materials for strength and stability.

Leg Design – Single-column legs for better support and safety.

Lower Crab Design – Main and auxiliary hooks below the girder for multi-point lifting.

Cross-Operation – Upper and lower crabs can work interchangeably, saving time and labor.

Variable Speed Control – All motors use frequency conversion for precise, smooth, and energy-efficient operation.

This gantry crane combines the strengths of bridge cranes with outdoor mobility, making it essential for shipyards and large marine construction sites.

Example Delivery:

A recently delivered 300-ton model (60m lift, 60m span) is compact yet powerful, improving assembly efficiency and competitiveness.

User-Focused Improvements:

Added sensors and optimized algorithms for precise alignment during frequent short-distance moves.

Customized training and interface adjustments based on user habits.

In shipbuilding, this gantry crane transports and assembles parts, making production faster and more flexible.

ME Shipbuilding Gantry Crane

The ME Shipbuilding Gantry Crane is a high-performance crane designed for heavy loads, large spans, and high lifting. It is used in shipbuilding, offshore construction, and industrial lifting. It is built for safety, precision, and efficiency in tough conditions.

Key Features

Multi-Functional Lifting

Handles single lifts, tandem lifts, mid-air flipping, and slight rotation.

Dual-crab system (upper and lower) allows cross-operation for higher productivity.

Strong Structure

Single or double girder options to save materials.

Variable-section girders for better strength and weight balance.

High-strength steel for heavy, continuous loads.

Smart and Safe Control

PLC and frequency converter for smooth, automatic lifting.

Safety monitoring with multiple protections.

Storm-proof design with rail clamps and anchors.

High Precision and Energy Saving

Automatic positioning with millimeter accuracy.

Single-side dual rails reduce wheel pressure and construction costs.

10KV power (750T model) with energy recovery, saving 25–30% power.

Easy Maintenance

Dedicated jib crane for servicing upper/lower crabs.

Corrosion-resistant coating for marine environments.

Why Choose This Crane?

Heavy-duty for shipyards, ports, and offshore projects.

Energy-saving with power recovery.

Smart controls reduce errors and improve precision.

Storm-resistant for harsh weather.

Low maintenance with easy access points.

This crane is ideal for shipyards, dry docks, and ports where heavy, high-lift operations like hull repairs and segment assembly are common. It handles:

Single/double lifts – For ship plates, engines, and modules.

Mid-air flipping – No ground contact needed, saving time.

Dual-crab teamwork – Upper and lower crabs work together, boosting efficiency by 50%.

Rigid + flexible legs ensure stability, while PLC control makes operation simple and safe.

The ME Shipbuilding Gantry Crane is built for moving, assembling, and turning large ship parts. It works in shipyards, offshore sites, and heavy industries.

Ship Hull Assembly

Moves ship parts (ribs, steel plates, bulkheads) from storage to work areas.

Flips and aligns hull sections mid-air for welding.

Shipyard Material Handling

Carries heavy loads across large docks quickly.

Multiple cranes work together without interference.

Offshore Construction

Lifts and positions offshore platform modules.

Syncs with other cranes for oversized loads.

Heavy Industry

Handles large steel parts for bridges, power plants, and factories.

Installs heavy pressure vessels safely.

Storm-Proof Operation

Stays stable in bad weather with rail clamps and anchors.

Fast, long-span movement – Saves time in big shipyards.

Dual-crab system – Lifts and turns hull parts at the same time.

Energy-saving – Recovers power, cutting costs by 25–30%.

Precision control – Reduces errors in hull alignment.

Gantry frame – Strong double-girder design (rigid + flexible legs).

Upper/lower crab system – Independent hoists for flexible lifting.

Travel system – Smooth movement along rails.

Safety features – Anti-collision, anti-tip, storm anchors.

PLC control – Automated, easy-to-use system.

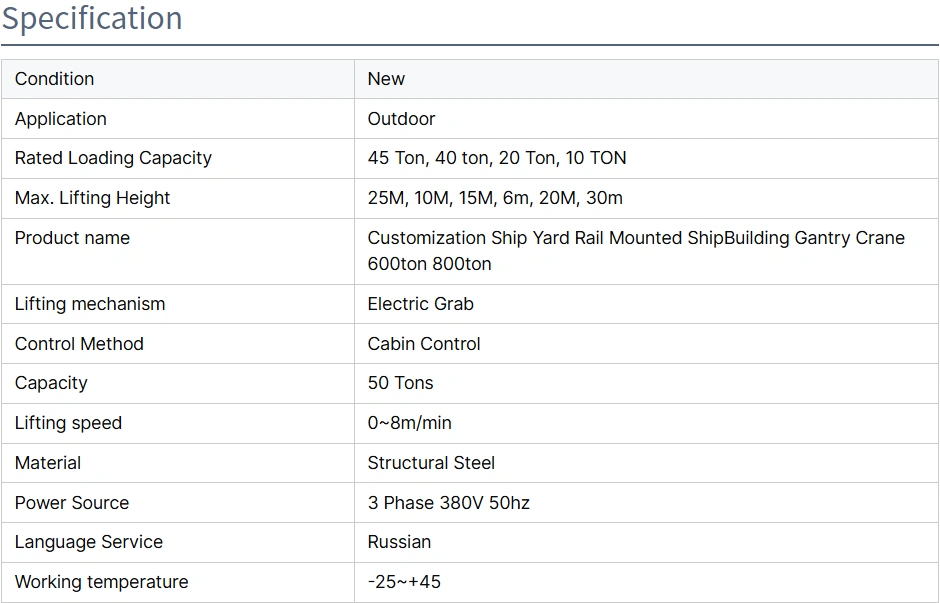

Capacity:

Upper crab (2 hooks): 2×75t

Lower crab (main/auxiliary hook): 110t/25t

Combined lifting: 220t

Height/Span: 50m / 83m

Lifting speed: 0–15 m/min

Wind resistance: ≤20 m/s (working), ≤40 m/s (non-working).

Mid-air flipping – Flips ship sections 180° without stopping.

Double-column rigid leg – Strong support with built-in elevator.

Layered girder design – Easier transport and assembly.

Follow-up maintenance crane – Easy repairs.

Low-voltage cable power – Safe, efficient energy supply.

Wechat:

+86 16627702870