Proven Performance

Quality Assurance

High-Strength Steel : Rigorously tested materials.

FEA-Optimized Structure : Even stress distribution for long-term durability.

Precision Controls : PLC + variable frequency drives for smooth operation.

Multiple Safeguards : Overload protection, limit switches, and emergency brakes.

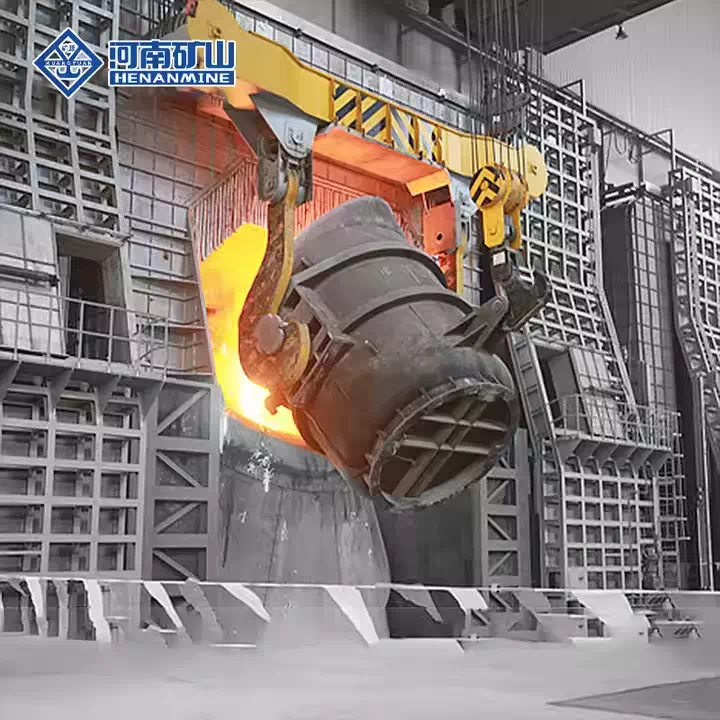

Four Girder Ladle Crane – Key Benefits & Features

1. Heavy-Duty & Reliable Design

Four-Girder & Four-Rail Structure : Provides maximum load capacity and stability for molten metal handling.

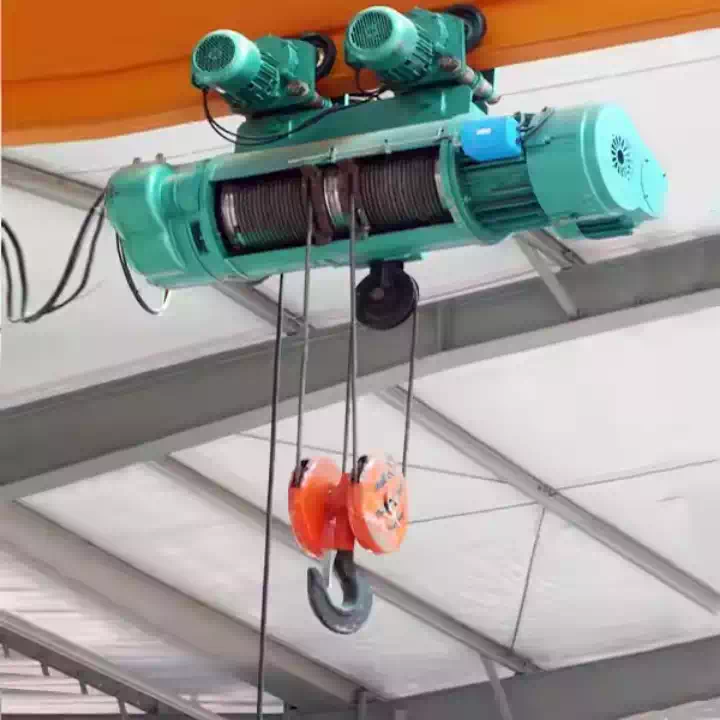

Dual Crab System (Main + Auxiliary) : Main crab lifts ladles; auxiliary crab assists in pouring.

Four-Corner Drive : Ensures smooth trolley movement and reduces wheel slippage.

2. Heat & Stress Resistance

Thermal Baffle & Insulation : Shields the girder from extreme heat.

Rock Wool Insulation & Air Cooling : Keeps electrical panels cool for longer lifespan.

Two-Stage Welding : First welding sets dimensions; second welding relieves stress for durability.

3. Precision & Safety for Molten Metal

Electronic Scale & Real-Time Monitoring : Displays weight in cabin and bridge for accuracy.

Dual-Wire Rope Safety : Backup ropes prevent accidents if one fails.

Multiple Brakes : 4 main lift brakes + 2 per lifting point + overspeed protection.

Anti-Collision & Limit Switches : Wireless sensors and dual travel limits for safety.

4. Customizable for Harsh Environments

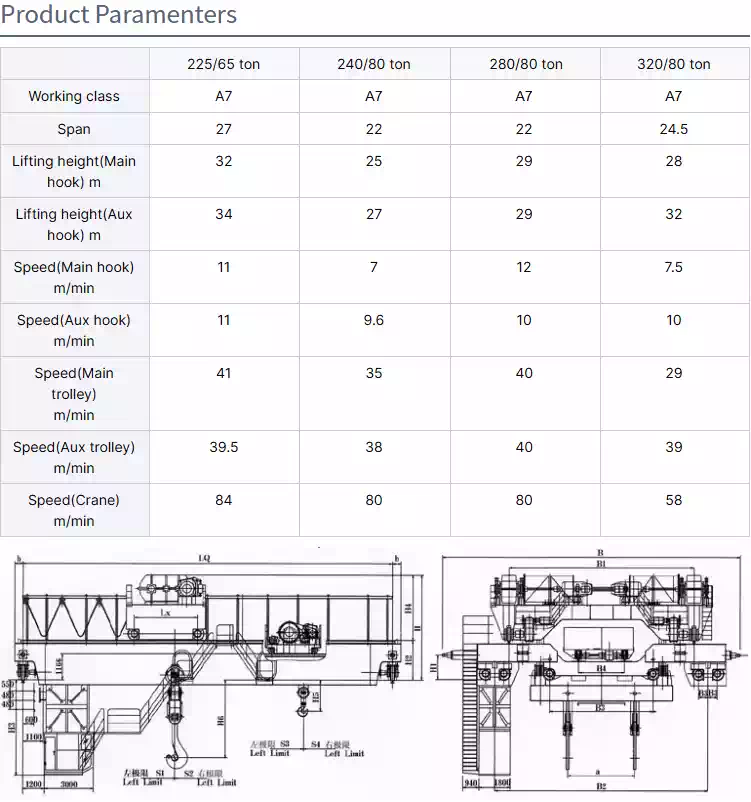

Adjustable Speeds : Lifting and travel speeds can be modified as needed.

Wide Temperature Range : Operates from -10°C to +60°C (ideal for steel plants).

Power Options : Standard 380V, 50Hz or custom voltage/frequency.

5. Advanced Safety & Electrical Protections

Overload Protection : Blocks lifting (only allows lowering if overloaded).

Anti-Falling Mechanism : Locks motor to prevent drops.

Safety Hook Latch : Prevents load slippage.

Other Protections :

Overcurrent, short-circuit, and phase-sequence safety.

IP54/IP55 dust/water resistance.

Emergency stop and zero-position protection.

6. Built for Extreme Industrial Use

High Capacity (125/32T+) : Handles ultra-heavy ladles with stability.

A7 Work Class : Designed for continuous foundry operations.

Precise Pouring Control : Dual-crab system ensures accurate steel pouring.

Why Choose This Crane?

✔ Stability : Four girders + dual lifting points minimize sway.Safety : Redundant brakes, ropes, and anti-fall systems.Heat Resistance : Engineered for long-term high-heat exposure.Smart Monitoring : Real-time weight tracking.Customizable : Adapts to tough conditions.

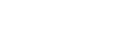

Lifting hook

Lifting hook

Container spreader

Container spreader