Explosion-Proof Crane Working Conditions

1. Environment Requirements

(1) Indoor Use (outdoor use needs agreement).

(2) Good Ventilation Needed – Must have proper airflow.

(3) Explosive Gas Areas (GB 3836.14-2014):

Zone 1: Explosive gas may sometimes be present.

Zone 2: Explosive gas rarely appears (if so, only briefly).

(4) Explosive Dust Areas (GB 12476.1-2013):

Zone 21: Dust clouds may sometimes form (e.g., near open containers).

Zone 22: Dust clouds rarely form (if so, only briefly).

2. Safety Rules for Workers

✔ Know Explosion Risks – Operators must understand crane safety.

✔ Smooth Starts & Stops – Avoid wheel slipping or sparks.

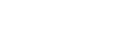

✔ Lubricate Steel Ropes – Reduces friction with pulleys and drums.

Key Notes for Safe Use

No Sparks – Avoid rough movements that cause friction.

Check Equipment – Ensure brakes, ropes, and electrical parts work well.

Follow Standards – Always meet GB 3836 and GB 12476 rules.

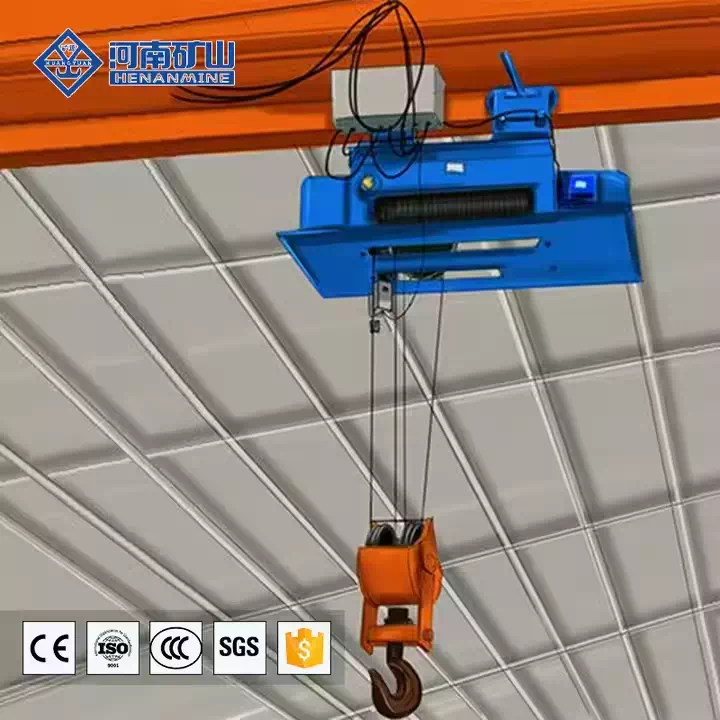

LDY Single Girder Overhead Metallurgy Crane – Applications

The LDY Single Girder Overhead Metallurgy Crane is a heavy-duty crane for high-heat industrial work. It is stronger and safer than standard cranes.

1. Steel Mills & Foundries

✔ Molten Metal Handling – Safely lifts and moves hot steel, iron, and other metals.

✔ Casting & Pouring – Helps in foundry work with precise lifting and tilting.

✔ Continuous Casting Lines – Keeps steel production running smoothly.

2. Warehouses & Material Stockyards

✔ Heavy Load Transport – Moves raw materials, ingots, and finished metal products.

✔ Workshop Logistics – Handles large coils, molds, and heavy parts in factories.

3. High-Temperature Work Areas

✔ Heat & Dust Resistant – Works well near furnaces and kilns.

✔ Corrosion Protection – Good for chemical plants and humid places.

4. Custom Industrial Uses

✔ Special Attachments – Can use hooks, grabs, or magnets for different jobs.

✔ Smart Factory Use – Works with automated Industry 4.0 systems.

Why Choose the LDY Metallurgy Crane?

✅ Extra Safety – Stronger build for molten metal work.

✅ Wider Use – Works in warehouses, foundries, and outdoor yards.

✅ Longer Life – Handles heat, dust, and heavy loads.

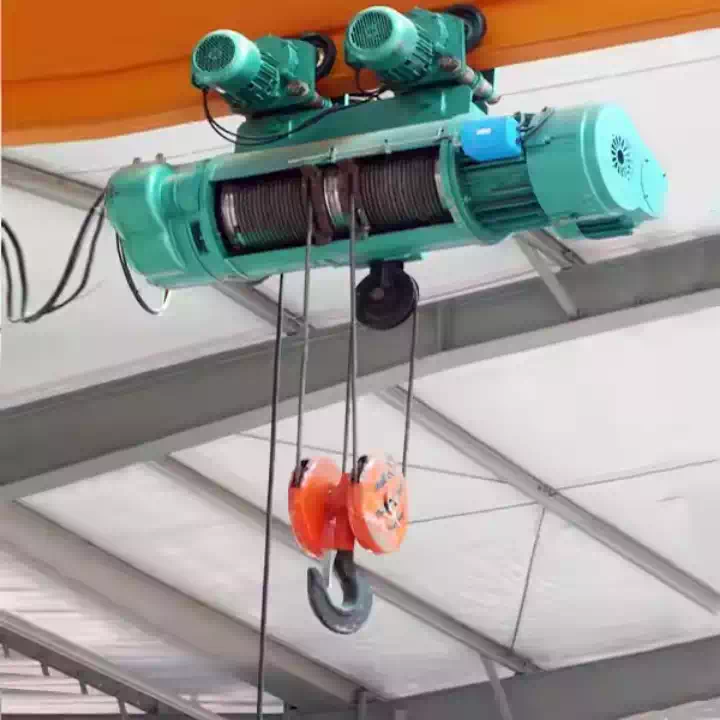

Lifting hook

Lifting hook

Grab bucket

Grab bucket