- A3

-

Grab bucket

Grab bucket

Grab bucket

Grab bucket

This crane works well with bulk materials like coal, grain, and scrap metal. It can use different tools such as grabs, spreaders, suction cups, and chains. It is good for waste recycling, foundries, and ports because it can handle many types of loads.

The single girder design makes the crane lighter but still strong and stable. It works best for light to medium loads and has an efficient electric grab system.

The crane runs on high rails (mounted on concrete or steel supports). This keeps the ground clear for cargo or workers. It moves along the rails to cover the whole work area without blocking the floor.

You can control the crane in two ways:

From the ground (remote or pendant) for safety in dangerous areas.

From an air cabin (open or closed) placed on the left or right.

The cabin can be entered from the side or end to fit different workspaces.

Main beam: Made of U-shaped steel and I-beam for strength without extra weight.

End beams: Box-shaped welded steel for durability and even load support.

Track options: Can be welded, bolted, or fixed with hook bolts to match site needs.

Uses soft-start motors and disc brakes for jerk-free operation.

Travels at 20–30 m/min for fast material handling.

Hoist and crane movements are controlled separately.

Uses top international electrical brands for long life and less downtime. Power is supplied through seamless sliding lines for steady performance.

The conical rotor motor gives high starting torque for heavy grabs. The lightweight grab system saves energy while keeping precision.

The single girder design costs less to install and maintain than double girder cranes. Bolted parts make repairs and replacements easy.

This crane is popular in:

Warehouses

Steel plants

Ports and logistics centers

Recycling facilities

✅ Custom solutions: Tracks, controls, and attachments can be tailored.

✅ Saves energy: Efficient motors and lightweight design.

✅ Meets global standards: Follows international safety and performance rules.

A grab bridge crane uses a grab as its lifting tool. It can unload, stack, transport, and feed materials. It is widely used in factories for general lifting and special tasks with grabs.

Main parts: Box-shaped bridge, grab trolley, trolley movement system, driver’s cabin, and electrical controls.

Grab: A tool to pick up loose materials.

The grab has two systems: one to open/close and one to lift.

Four steel ropes connect to these systems.

To grab material, the close system shuts the grab. Then the lift system raises it evenly.

To unload, the open system releases the material.

Except for the lift system, grab cranes are similar to hook cranes.

Design: Follows JB/T 1306 standards. Works with electric grabs for automatic material handling.

Main beam: Made of high-quality I-beam and U-shaped steel.

End beams: Welded steel tubes or plates.

Connection: Uses high-strength bolts (10.9 grade).

Lifting: Two electric hoists (one for lifting, one for opening/closing the grab).

Grab sizes: 0.5–1.5 m³ for materials under 1 ton/m³.

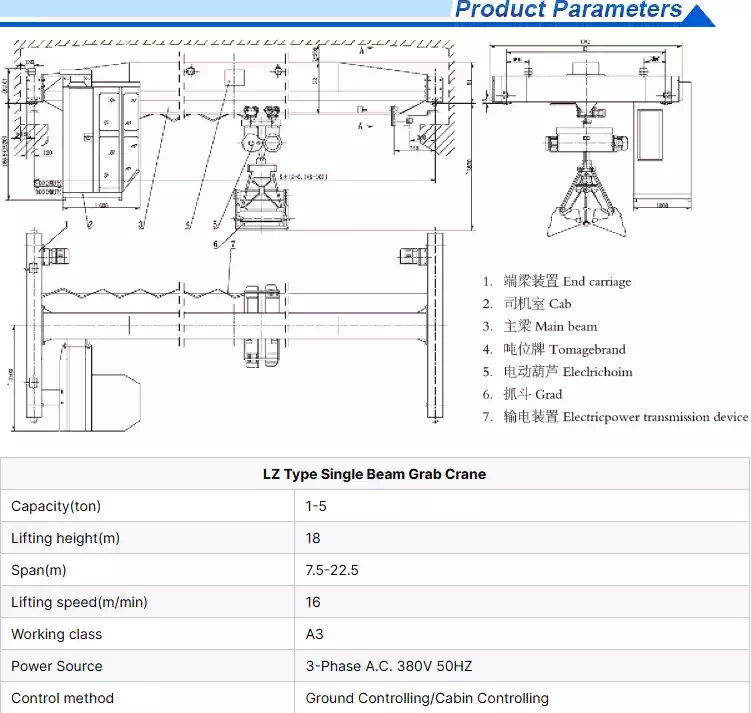

Lifting capacity: 2–5 tons.

Span: 7.5–22.5 m.

Works at -25°C to +40°C.

Strong, stable, and smooth operation.

Can use normal or variable speed.

Standardized parts for easy maintenance.

Good for small to medium loads.

Custom designs available.

Grab cranes (also called grabber cranes) are used in ports, mines, and stations for loose materials like coal, sand, and logs. They are automatic, reducing labor and saving time.

Bridge grab cranes

Gantry grab cranes

Foldable-arm grab cranes (common for logs)

Types: Double-rope (most common), single-rope, motor grabs.

Sizes: Light (for grain), medium (for gravel), heavy (for ore).

Jaw styles: Two-jaw (common) or multi-jaw (for large items like scrap metal).

Scissor grabs: Increase grip as they close, good for cleaning but not large items.

Toothed grabs: For materials over 200 mm.

Use: Move bulk goods from ships to conveyors.

Controls: Open or closed cabin.

Motor: Wound-rotor with speed control.

Works at: -20°C to +40°C (not for explosive/insulated areas).

Grab opens parallel or perpendicular to the beam.

Weight includes the grab.

Weather covers add height (H+h).

Outdoor cranes are 5% heavier.

Power: Angle steel or safe sliding lines.

Standard or weighing trolleys.

Special grabs for sugar cane, trash, wood, etc.

Single girder grab cranes move bulk materials fast and safely. They work well in many industries.

Moves scrap metal in recycling plants.

Handles trash and waste for sorting.

Loads coal, coke, and charcoal in power plants.

Transports sand, gravel, and cement.

Removes slag and metal scraps.

Feeds raw materials like iron ore.

Loads/unloads coal, grain, and fertilizer.

Moves goods between storage and trucks.

Handles cement and crushed stone.

Moves concrete blocks and debris.

Loads wheat, corn, and animal feed.

Moves fertilizer and seeds.

Feeds coal into boilers.

Clears ash and waste.

✔ Works fast with easy grab/release.

✔ Fits tight spaces.

✔ Needs little maintenance.

✔ Can use different grab types.

Best for:

Moving bulk materials

Heavy scrap

Dusty or rough areas

Used in power plants, warehouses, factories, and ports to move loose materials.

Works for heavy-duty tasks.

All controls are in the driver’s cabin. Entry doors can be on the side, end, or top.

The weight limit includes the grab’s own weight.

The grab can open parallel or straight to the main beam.

Only trained workers can operate.

Follow all company safety rules.

Check before work:

Clear path for the crane.

Tight rail fasteners.

Working buttons and limits.

Smooth hooks and ropes.

Good brakes and safety gear.

Sound alarms before moving near people.

If power cuts off, turn off all switches and call electricians.

No repairs while the crane is working.

Don’t move sideways and lift at the same time.

Secure loads properly before lifting.

Never lift buried or tilted objects.

No people or loose items on loads.

Don’t work in dark areas.

Keep at least 3 rope loops on the drum.

Don’t lift over people or vehicles.

Check for people before grabbing into bins.

Lower grabs fully and cut power before leaving.

Stop if you hear odd noises and fix issues first.

Clean up after work and park the crane safely.

Fire extinguishers are in the control room.

Dust and noise – wear masks and ear protection.

Not wearing safety gear.

Skipping equipment checks.

Not holding handrails on stairs.

Walking over machines.

Adjusting brakes while powered on.

Using broken safety limits.

Stopping with limit switches.

Fixing brakes under load.

Lifting unsecured items.

Forcing stops by reversing (unless emergency).

Lifting over obstacles.

Operating without a license.

Ignoring safety rules or hazards.

Wechat:

+86 16627702870