- A3

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

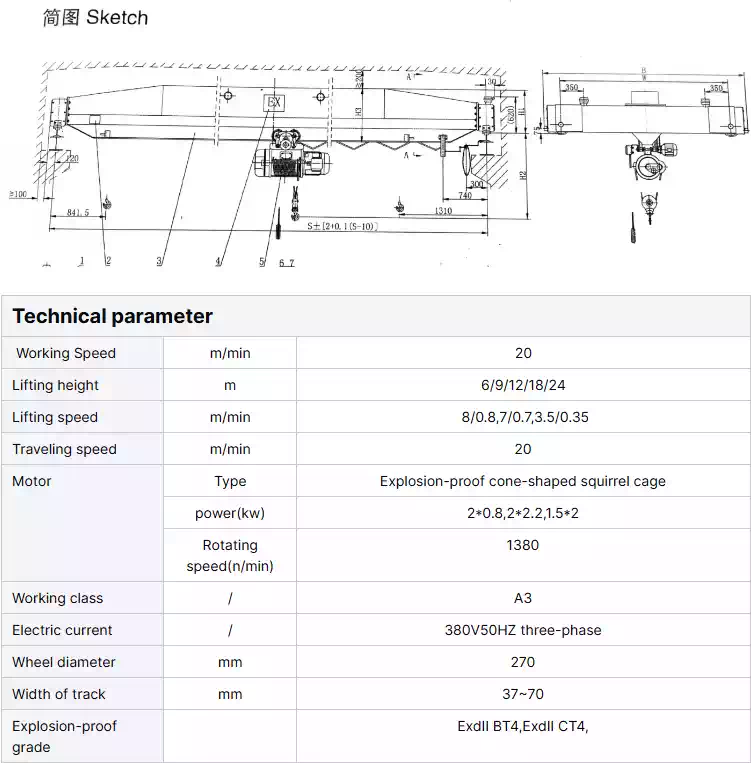

Explosion Proof Single Girder Overhead Crane – Key Advantages & Features

1. High Safety for Explosive Environments

Certified Protection: Meets ATEX & GB standards (JB/T10219-2001) with ExdII BT4/CT4 protection grades.

For Hazardous Areas: Works in Zone 1 & 2 (per GB 3836.1-2000), handling flammable gases (IIB/IIC) with ignition temps ≥ T4.

No Sparks: Travel mechanism prevents ignition in high-risk areas (when rated ExdII CT4).

2. Reliable Components

Explosion-Proof Parts: Hoist, motor, and controls use Exd-certified components.

Top-Quality Brands: Optional motors/gearboxes from leading suppliers.

Easy Control: Choose ground pendant or cabin operation.

3. Strong and Durable Design

Smooth Operation: Handles ≤120 starts/hour (25% duty cycle).

Heavy-Duty Build: Steel frame with anti-corrosion coating (custom options for outdoor use).

Easy Maintenance: Modular design for quick repairs.

4. Safety Protections

Overload Prevention: Stops motor burnout and damage.

Emergency Features: Includes stop buttons, limit switches, and hook latches.

Tested Quality: All parts checked before assembly.

5. Affordable and Efficient

Low Cost: High safety without high prices.

Fast Setup: Easy to install/dismantle.

Wide Use: Works in -20°C to 40°C, ≤85% humidity, and elevations <1000m.

Ideal for:

✔ Petrochemical plants

✔ Pharmaceuticals & chemicals

✔ Mining/oil rigs

✔ Grain silos & fuel storage

Additional Details (Translated from Chinese Content):

Design Basis: Improved from "LD-type" cranes per GB 3836.1/2-2000 standards, with stronger structure and explosion-proof features.

Compatibility: Pairs with BCD/BMD/HB explosion-proof hoists (0.5t–32t capacity, 7.5–22.5m span).

Operation Modes: Ground or cabin control (open/closed cabin, left/right entry options).

Usage Limits: For factories/warehouses; not for flammable, explosive, or corrosive environments.

Pre-Operation Checks:

Inspect main beam connections.

Check wheels for cracks/wear (replace if damage >3mm deep).

Ensure electrical wires are secure.

Verify proper grounding.

Operation Steps:

Test-run the crane and position it above the load.

Secure the load and lift.

Move carefully under supervisor’s guidance.

After use, park the crane, turn off power, and clean the area.

Safety Rules:

Operators must pass training and certification.

Follow the "10 No-Lift" rules (e.g., no overload, unsafe binds, or unclear signals).

Never lift over people; keep others away from loads.

Maintain 3+ wire rope loops on the drum.

Shut down and report faults immediately.

If power fails, set controls to zero and mark hazard zones.

Lower loads slowly—no free-falling.

Explosion Proof Single Girder Overhead Crane – Applications & Features

This crane is made for dangerous places with explosive gases, dust, or vapors. It works safely in high-risk areas.

Oil & Gas: Safe lifting in refineries, fuel storage, and LNG plants.

Chemical & Pharma: Handles explosive chemicals and solvents.

Paint & Coating: No sparks near flammable liquids like ethanol.

Mining & Coal: Works in methane or dust-heavy areas.

Grain & Food: Safe for flour, sugar, and starch dust.

Aerospace & Defense: Moves fuel tanks and propellants.

Waste & Biofuel: Resists corrosion in biogas areas.

✔ Zone 1 & 2 (explosive gases sometimes present).

❌ Not for Zone 0 (always explosive).

Gas Groups: IIB (propane, ethylene) & IIC (hydrogen, acetylene).

Temperature: Safe for gases with ignition temps ≥135°C (T4).

Conditions: Up to 85% humidity, below 1000m altitude.

No Sparks: ExdII CT4/BT4 motors and spark-proof design.

Follows Rules: Meets JB/T10219-2001 and ATEX standards.

Easy Control: Use from cabin or ground pendant.

Power Supply: Must have a main switch near the crane for easy access.

Wiring: Exposed power lines must be marked red and have warning lights.

Emergency Stop: Must be manual (not auto-reset).

Remote Control: Required for lifting hot metals to keep workers safe.

Models: LXB (suspended), LB (single girder), LHB (bridge type).

Capacity: 0.5–63 tons.

Span: 7.5–35.5 meters.

Temperature: Works in -25°C to +40°C.

Speed: Lifting (5–11 m/min), Moving (37–44 m/min).

Zone 0 (always explosive).

Wet, acidic, or alkaline areas.

Melting metals, toxic, or highly flammable materials.

Check needed specs: weight limit, span, height, etc.

Outdoor use? Add rain protection.

Custom orders available.

1-year warranty for normal use.

Paid repairs after warranty.

Wechat:

+86 16627702870