- A5

-

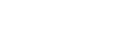

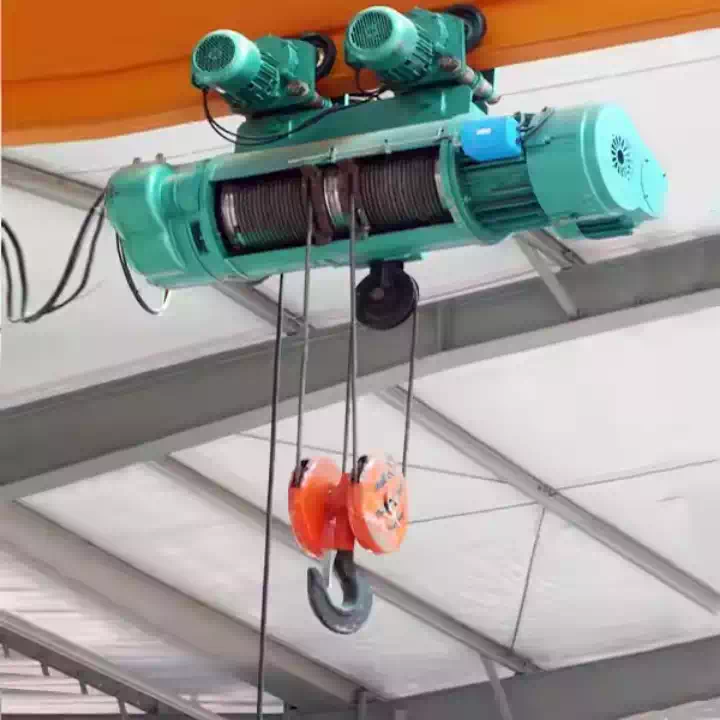

Lifting hook

Lifting hook

-

Grab bucket

Grab bucket