- A4

-

Lifting hook

Lifting hook

Lifting hook

Lifting hook

Single-leg design works in tight spaces. One side runs on ground rails, the other on elevated workshop rails.

Perfect for small-to-medium workshops, warehouses, and production lines needing flexible lifting.

Design benefits (Chinese content):

No ground rails needed, allowing obstacle-free transport and safer operation.

Factory floors remain unobstructed for forklifts or other equipment.

Easy installation, short setup time, and low investment cost.

Low load requirements on building structures.

European engineering ensures durability and meets global standards (CE, ISO, BV certified).

Electric hoist moves smoothly on I-beam girder for precise load handling.

Specifications (Chinese content):

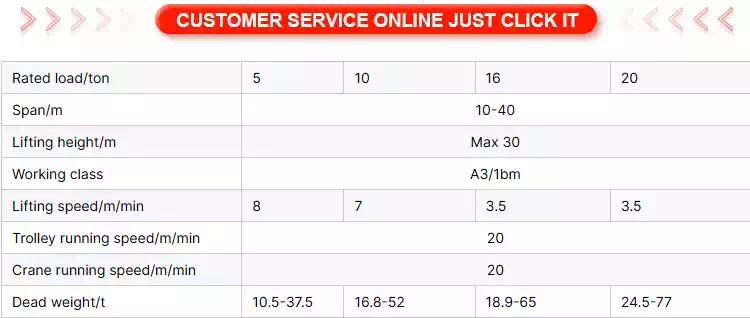

Capacity: Up to 10 tons.

Span: Up to 15 meters.

Works in medium-duty environments.

Quick installation, low structural load demands.

Overload protection and low-voltage safety devices prevent accidents.

Anti-collision systems, alarms, and rail clamps improve safety.

Self-checking circuit protection and limit switches for phase-loss prevention.

Safety (Chinese content):

All motors have overheating protection.

Dual-speed or frequency control for lifting.

Speed control for trolley and gantry movement.

Audible/visual alarms for gantry travel.

Simple design cuts installation time and costs.

Easy access to parts reduces downtime.

Rainproof options for outdoor use in harsh conditions.

Choose pendant or remote control.

Shields prevent hook clashes for safer workflow.

Options (Chinese content):

Anti-sway control for precise load positioning.

Synchronized lifting for dual hooks.

Micro-speed and inch-movement for accuracy.

Target positioning to automate repetitive tasks.

Trusted Maker: Henan Mine Crane Co., Ltd. is a top manufacturer with 120+ certifications, exporting to 30+ countries.

High Output: 4,000+ gantry cranes and 35,000+ single-girder cranes yearly.

Global Standards: CE, ISO, and BV certified for EU and international safety.

Innovation: "Hi-tech Enterprise" with R&D-driven designs for long-lasting performance.

"Quality Makes Brand, Honesty Weaves the Future" – We deliver durable, safe, and high-performance cranes for your needs.

Open-air storage: Moves heavy loads (pallets, raw materials) in yards with limited roof space.

Loading docks: Transports goods between trucks and storage areas easily.

Machinery plants: Handles parts, molds, and assembly lines in workshops with single-sided rails.

Steel fabrication: Lifts steel coils, beams, and plates safely in tight spaces.

Construction sites: Carries concrete blocks, pipes, and building materials. Truss outriggers add stability on uneven ground.

Biomass/pellet plants: Moves bulky organic materials in open-air facilities.

Forestry & lumber: Transports logs and timber in sawmills or storage yards.

Intermodal terminals: Loads/unloads shipping containers with flexible rail systems.

Concrete plants: Handles precast elements and heavy molds safely.

Reliable performance: Works in yards and factories without cantilever support.

Durable & low maintenance: Strong structure, long service life.

Custom solutions: Multiple configurations for different needs.

Optional flat rail or track operation.

Modular design: lifting mechanism, main beam, legs, control box, safety systems.

Drive system: Maintenance-free motor + hardened gear reducer + disc brake.

Control options: Wired (IP65), wireless remote, or cabin operation.

Safety features: IP54 protection, F-class insulation, anti-sway wire rope, alarms.

Space-saving design: One end runs on elevated rails, the other on ground tracks. Saves cost and floor space vs. full gantry cranes.

Wide adaptability: High site utilization, broad coverage, strong versatility.

Fits tight spaces: Single-leg design works where full gantries cannot.

Indoor/outdoor use: Rainproof and reinforced options for tough conditions.

Safety certified: Anti-collision alarms, rail clamps, CE/ISO compliance.

Wechat:

+86 16627702870